The Beginnings of Engineering Ceramics

Engineering ceramics have roots that dig deep into the past. You can trace their origins back hundreds, even thousands, of years. Folks were churning out ceramics for pots and pans, much like how they crafted tools for farming. But, as time slipped by and technology hitched a ride, the game started to change. These engineering ceramics began to take on new roles, especially in industries that needed materials tough enough to handle heat and wear. They stepped into the spotlight as reliable options for everything from machinery parts to dental procedures, demonstrating their versatility. It was a gradual evolution, but one that made a significant impact on how we approach manufacturing today.

The Types of Ceramics in Engineering

When it comes to the types of ceramics in engineering, understanding what you’re dealing with is key. These materials can vary widely, and each type comes with its own set of properties suited for specific tasks. Some ceramics handle high temperatures like a champ, while others provide incredible resistance to corrosion. This broad spectrum means that engineers can select the right kind for their needs, whether they’re working in aerospace or creating intricate components for automotive applications. Knowing the differences helps folks make informed choices, ensuring they get the best performance from these hardworking materials.

Diving Deeper into Engineering Ceramics

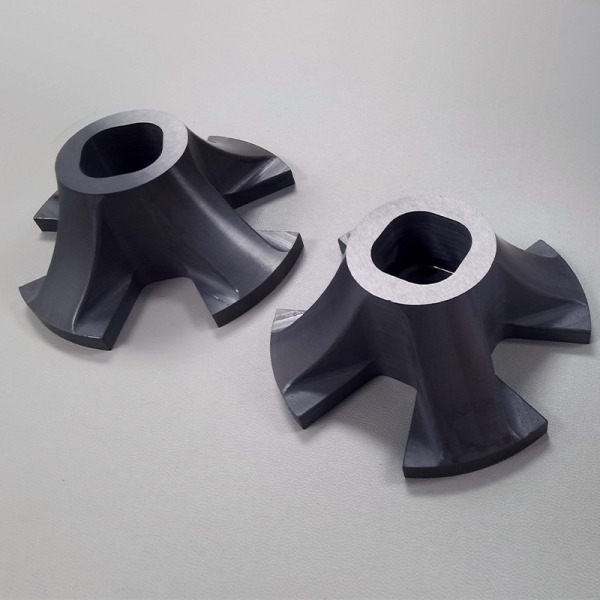

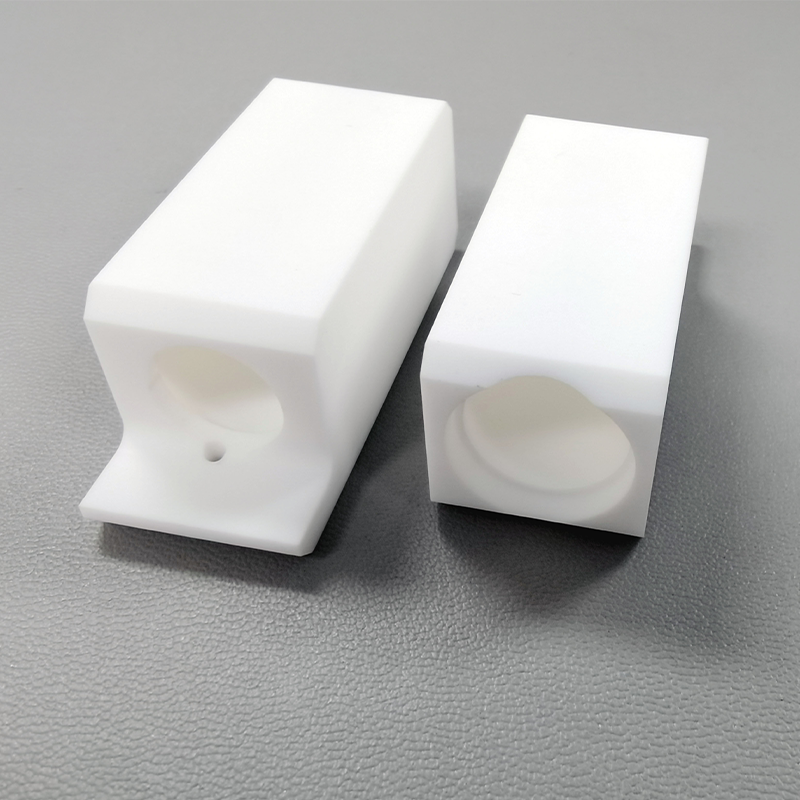

When you talk about engineering ceramics, it’s all about quality. The manufacturing processes have come a long way, from traditional methods to high-tech approaches that rely on cutting-edge science to create these materials. Stronger, tougher, and more reliable than ever before, these ceramics are what many industries rely on these days. Be it cutting tools in a workshop or insulators in electronic devices, the capability of engineering ceramics to adapt and excel in various conditions makes them invaluable. With ongoing research, they continue to improve, promising even brighter futures in industrial applications.

Conclusion and Brand Recommendation

In summary, engineering ceramics have transformed from humble beginnings into essential components in today’s technology-driven world. The many engineering ceramic options available cater to different needs across various sectors. If you’re looking for a reliable source of these materials, you might want to turn your attention to Great Ceramic. This brand stands out as a manufacturer with supply advantages, ensuring that companies can get high-quality ceramics when they need them, without the long waits or uncertainties that sometimes plague the supply chain.